Choosing the Right Kind Of Spray Foam for Your Insulation Demands

Choosing the Right Kind Of Spray Foam for Your Insulation Demands

Blog Article

Spray Foam: The Ultimate Solution for Air Sealing and Insulation

Spray foam insulation has arised as a leading service for reliable air sealing and thermal insulation, supplying a distinct combination of properties that establish it apart from typical approaches. Comprehending the full range of its benefits, installation processes, and contrasts with various other insulation kinds is important for making educated choices.

What Is Spray Foam?

Spray foam is a versatile insulation product that incorporates the concepts of air sealing and thermal resistance to improve energy effectiveness in buildings. Made up largely of polyurethane or other comparable compounds, spray foam is used as a liquid that broadens upon contact with surface areas, creating a strong, continuous layer of insulation. This one-of-a-kind building enables it to load gaps, cracks, and voids that traditional insulation materials might neglect, offering a premium air seal.

There are two major kinds of spray foam: open-cell and closed-cell. Open-cell spray foam is lighter and more flexible, offering outstanding audio absorption and a lower R-value per inch - Spray Foam. In comparison, closed-cell spray foam is denser, supplying a higher R-value, wetness resistance, and added structural stability to building parts

The application procedure typically entails specific equipment, guaranteeing a seamless application that follows different substratums, consisting of concrete, timber, and steel. This adaptability makes spray foam suitable for both brand-new building and constructions and retrofitting existing frameworks. Its ability to produce a closed obstacle dramatically contributes to lowering power usage and improving interior air high quality, therefore making it a favored choice amongst homeowners and contractors alike.

Benefits of Spray Foam Insulation

Among one of the most significant advantages of spray foam insulation is its outstanding capacity to develop a continual air obstacle, which properly lessens power loss. Unlike typical insulation materials, spray foam broadens to fill splits and spaces, ensuring that air leak is significantly minimized. This characteristic not only improves power efficiency but also results in decrease utility bills with time.

Additionally, spray foam insulation provides exceptional thermal resistance, contributing to a more steady interior environment. Its high R-value per inch permits reliable insulation in confined areas, making it excellent for attics, wall surfaces, and crawl areas. In addition, the moisture-resistant homes of spray foam assistance protect against mold and mildew and mildew development, promoting healthier living problems.

An additional important advantage of spray foam insulation is its sound-dampening top qualities (Spray Foam). It efficiently minimizes sound transmission between rooms, producing a quieter and more comfortable home setting. The resilience of spray foam additionally stands apart, as it does not sag or settle in time, maintaining its performance throughout its lifespan

How Spray Foam Works

Recognizing just how spray foam insulation functions is necessary for appreciating its efficiency in air securing and thermal resistance. Spray foam insulation contains two key elements: isocyanate and polyol material. When these components are mixed, they undergo a chemical reaction that causes the product to increase quickly, developing a dense foam that loads fractures, cavities, and gaps.

As the foam broadens, it complies with surface areas, creating an airtight seal that significantly reduces air seepage. This characteristic makes spray foam insulation highly effective at stopping drafts and dampness infiltration, which can bring about energy loss and damage in time. Furthermore, the closed-cell version of spray foam uses exceptional thermal resistance as a result of its inflexible structure, properly reducing warmth transfer.

The one-of-a-kind buildings of spray foam enable it to comply with uneven surfaces, guaranteeing extensive protection and a seamless obstacle. Because of this, Resources spray foam insulation not only improves energy performance however also adds to enhanced interior air top quality by reducing the accumulation of irritants and toxins. Inevitably, understanding the auto mechanics behind spray foam underscores its function as a remarkable option for insulation and air sealing in both commercial and residential applications.

Installation Refine Introduction

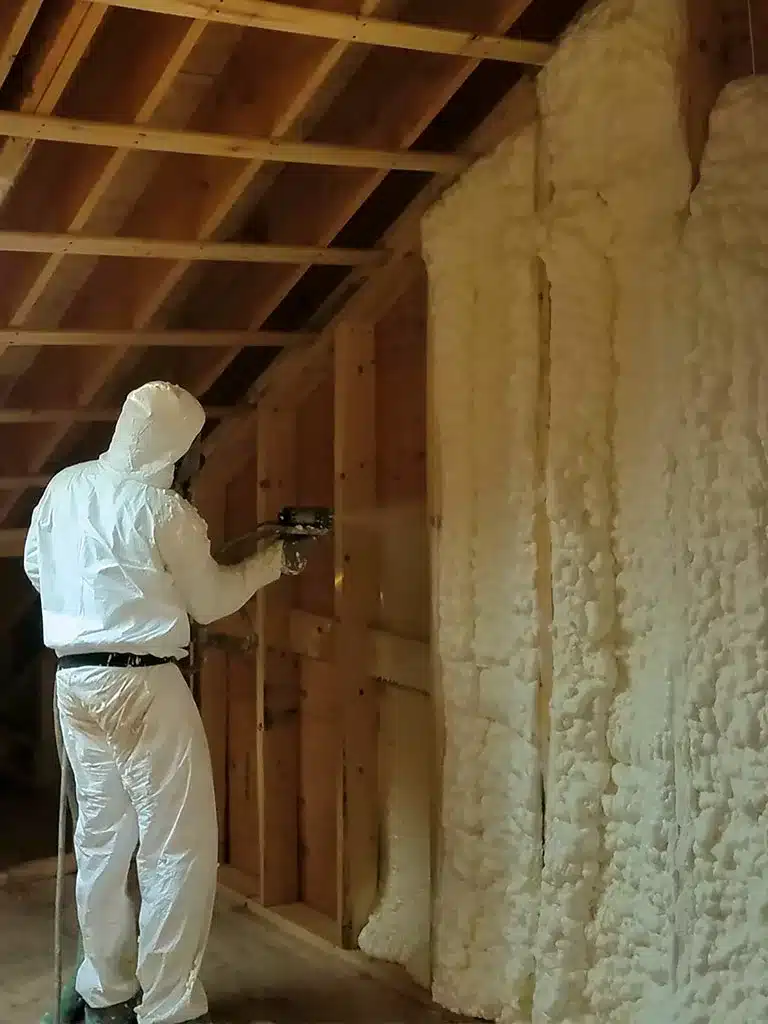

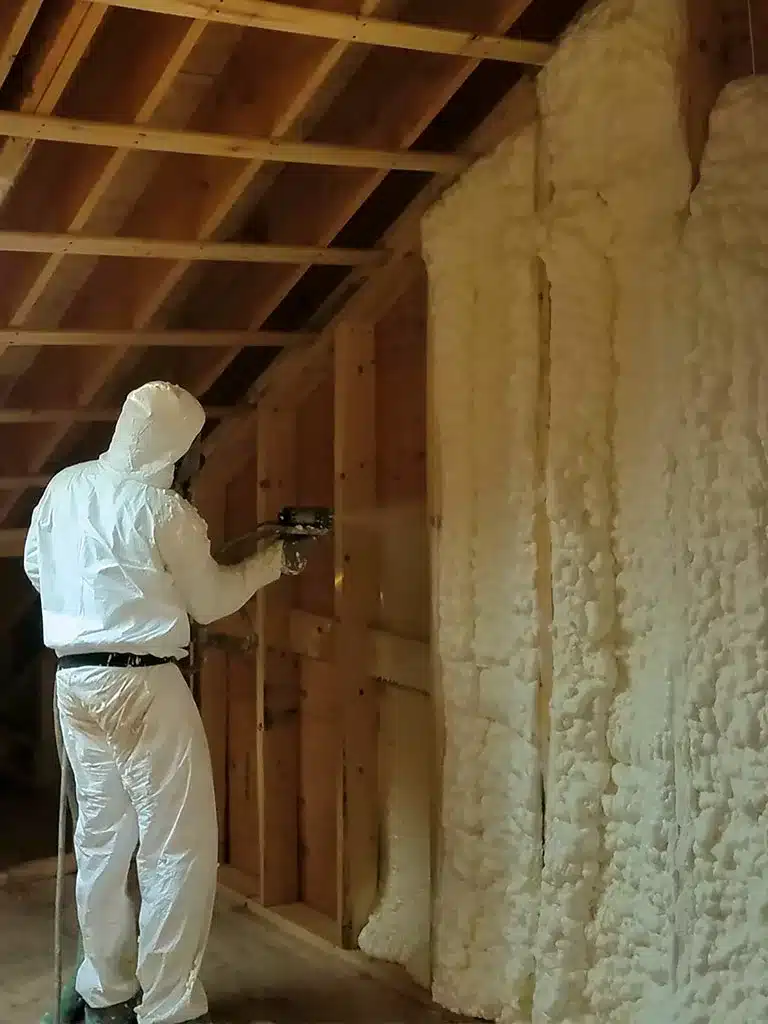

Before installment, the area must be effectively cleansed and prepped, guaranteeing that surface areas are cost-free from dirt, particles, and dampness. This action is essential since contaminants can jeopardize adhesion and general efficiency. When the area is prepared, the application entails blending the 2 elements of the spray foam, which expands upon contact and fills up gaps properly.

Trained specialists ought to carry out the setup, using specific tools to make certain consistent coverage and ideal density. Security preventative measures, consisting of putting on protective equipment and ensuring proper air flow, are vital during this procedure. After application, the foam usually remedies rapidly, developing a strong barrier that improves energy performance.

Contrasting Spray Foam to Traditional Insulation

When reviewing insulation choices, spray foam insulation stands apart in contrast to traditional materials such as fiberglass and cellulose. Among the key benefits of spray foam is its exceptional air sealing capacities. Unlike fiberglass and cellulose, which can enable air infiltration, spray foam increases upon application, loading voids and holes to create an impermeable seal. This results in improved energy effectiveness, as much less heated or cooled air leaves the home, leading to lower energy costs.

Furthermore, spray foam gives a greater R-value per inch than typical insulation kinds, using even more effective thermal resistance in a thinner account. This characteristic is especially valuable in rooms with limited cavity deepness. Spray foam is immune to dampness and mold growth, which can be a substantial concern with cellulose and fiberglass, particularly in damp settings.

However, spray foam insulation normally brings a higher upfront cost than its standard counterparts. Homeowners should weigh this preliminary investment versus long-lasting energy savings and performance benefits. Inevitably, while both insulation kinds offer their objective, spray foam becomes an advanced service for modern insulation pop over to this site needs, specifically in terms of air securing and thermal performance.

Final Thought

In summary, spray foam insulation represents a very reliable remedy for accomplishing ideal air securing and thermal resistance. Its distinct residential properties, including wetness resistance and audio dampening, make it appropriate for various applications in both brand-new building and constructions and retrofitting tasks (Spray Foam). The first prices may be higher compared to standard insulation materials, the long-term advantages, such as significant power cost savings and boosted indoor air quality, validate the financial investment and emphasize its value in modern-day structure methods.

Spray foam insulation has emerged as a leading service for reliable air sealing and thermal insulation, offering a special mix of buildings that set it apart from typical approaches.Spray foam is a functional insulation material that incorporates the principles of air securing and thermal resistance to boost power efficiency in buildings.When evaluating insulation alternatives, spray foam insulation stands out in contrast to traditional products such as fiberglass and cellulose. Eventually, while both insulation kinds offer their you can find out more objective, spray foam emerges as a much more sophisticated remedy for modern insulation demands, particularly in terms of air sealing and thermal efficiency.

In summary, spray foam insulation stands for an extremely reliable remedy for attaining optimum air sealing and thermal resistance.

Report this page